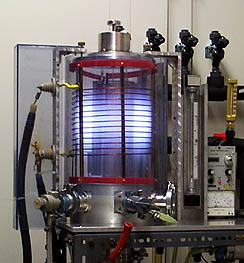

The multilayer magnetometers described here are based on two superconducting YBa2Cu3O7 layers and an intermediate SrTiO3 layer for their insulation. Both types of thin-films are deposited by off-axis rf magnetron sputtering in an Ar/O2 atmosphere. The patterning of the thin-films is done by conventional photolithography and Ar-ion beam etching. Single layer magnetometers have also been prepared by a pulsed laser deposition process using a 248 nm KrF Excimer laser.

Multilayer Technology

Pulsed Laser Deposition

Oxygen Plasma Treatment

Measurement and characterization

-

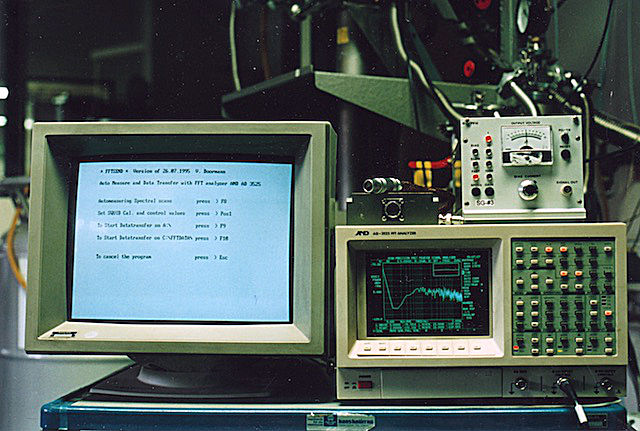

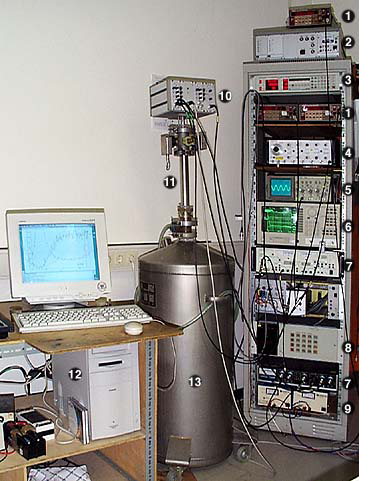

The measurement setup. Multimeter,

- SQUID FLL electronics,

- Temperature controller,

- Waveform generator,

- Oscilloscope,

- FFT signal analyzer,

- Lock-in amplifier,

- Multi purpose data acquisition unit,

- Lead acid battery chargers,

- Battery powered modular SQUID electronics,

- Probe holder,

- Apple Power Macintosh,

- Liquid nitrogen dewar.

All instruments are connected via GPIB Bus to an Apple Power Macintosh (More details).